DISCO large-scale mowers from CLAAS have been making their mark in the professional forage harvesting sector for large farms and contracting work for 25 years. The introduction of AUTO SWATHER swath grouping in 2011 greatly increased the versatility of these machines. Since 2023, the DISCO 9700 RC AUTO SWATHER, one of the more powerful biomass mowers on the market, has taken efficiency and reliability to a new level for customers working in the most challenging conditions with exceptional crop volumes of up to 60 t/ha – thanks to the double roller conditioner with new HD drive concept and XXL belts designed specifically for crop flow in the roller conditioner.

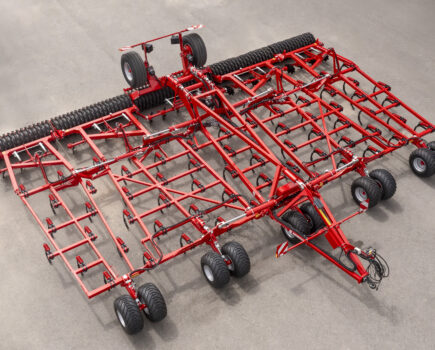

Read more: Swath grouping with or without conditionerCLAAS has added two models with a 9.10 m working width to the product range, and now offers four performance classes for large-scale mower-conditioners for power outputs from 180 to over 400 hp.

DISCO 9300 DIRECT SWATHER: spreading without a conditioner

For farms which do not need a conditioner because they require longer wilting processes or have less powerful tractors, CLAAS has taken the tried and tested auger technology from the DIRECT DISC front attachment on the JAGUAR forage harvester and systematically redeveloped it for grassland use in the new DIRECT SWATHER.

Designed for forward-thinking dairy farms, the DISCO 9300 DIRECT SWATHER large-scale mower features a host of clever details which for the first time provide four mowing and swath-laying strategies in this segment:

- Full-width deposition for fast, effective wilting.

- Mowing with integrated central swathing for fast, effective field clearance without tedding and swathing.

- 18 m mowing width consolidated to 12 m swath (combined swath/wide placement) for active control of witing process and optimal forage harvester utilisation.

- Mowing with one-sided swath laying for clearing the field margin.

Flexible swath-laying without a conditioner – no problem with the new DISCO 9300 DIRECT SWATHER.

By dispensing with the conditioner, the innovative large-scale mower can be operated with tractors from 180 hp, and so extremely efficiently. Furthermore, it is suitable for all crops and all conditions – from high-yielding green rye for biomass production to gentle mowing of alfalfa or late-season cuts of grassland with low growth. When dealing with low volumes of growth, especially in regions with low rainfall and a high number of sunshine hours, the absence of conditioner prevents too rapid wilting of the crop and enables active control of the DM content. The augers can be swung open for targeted control of the drying process and optimal adjustment of swath laying to the volume of growth and downstream harvest chain.

Tapered auger design for superior crop flow

The tapered CLAAS auger arranged close and parallel to the mowing discs ensures consistent, reliable crop pick-up even when growth is uneven. At the same time, the tapered design increases the feed volume towards the middle, as the increasing diameter of the auger enables more crop to be conveyed. In addition to the tapered design of the auger, the tapered auger housing with integrated ‘pockets’ in the rear is another unique feature. These pockets expand the available space, thereby significantly increasing the feed volume and thus the throughput.

Shear bar and knives at the auger outlet prevent crop build-up and so guarantee blockage-free operations.

Perfect coordination of mower bed, auger and auger housing pockets ensure uniform, blockage-free crop flow with minimum power requirement and maximum fuel efficiency. Early results indicate that the fuel consumption can be up to 40 percent lower than comparable equipment with conditioner.

Swathing plates mounted on the central console guide the crop flow under the mower frame. Additional hydraulically pivoting and adjustable swath curtains prevent crop being thrown out during one-sided swath laying. This ensures uniform swath formation under all conditions, maximising the efficiency of the downstream harvest chain.

Pivoting auger for fuel-efficient, full-width deposition

When mowing without conditioning, it is important to be able to use the full mowing width as a wilting area. The top-mounted auger drive in the DISCO 9300 DIRECT SWATHER enables the augers to be swung open hydraulically at any time, allowing the unprocessed crop to be deposited across the full mowing width. The augers can be conveniently swung open or shut individually or in parallel via ISOBUS – even while mowing is underway.

The unique design with tapered augers, large-volume conveyor channel and top-mounted drives as well as crop flow behind the augers enables high, blockage-free throughput.

The control concept: with intelligent suspension, you can relax

The standard ACTIVE FLOAT mower suspension can be adjusted to suit the harvest conditions via ISOBUS while mowing is underway. Working with the lowest ground pressure ensures forage-friendly, crop-friendly and fuel-efficient mowing. The optional CLAAS automatic slope control function regulates the ground pressure differently depending on whether you are mowing up- or downhill to reduce side drag and so minimise misalignment between front and rear mowers. What’s more, this form of electronic operator assistance enables sward-friendly slope work even in wet conditions.

For ultimate operator comfort, mower lifting is integrated directly into the tractor’s headland management system, while the mower’s load-sensing hydraulics are controlled directly via the ISOBUS on the tractor or the CEMIS 700 or CEMIS 1200 CLAAS ISOBUS terminals.

DISCO 9300 C AUTO SWATHER: with conditioners for all crops

The new DISCO 9300 C AUTO SWATHER uses the conventional steel tine conditioner to pick up the mown crop behind the mowing discs and feed it to the cross conveyor belts. Although this has a higher power requirement, it guarantees reliable crop flow in all crops, even under challenging conditions. In addition, cross conveyor belts featuring speed control produce a particularly airy, uniform swath which results in higher throughput with a lower power requirement in the downstream harvest chain.

The integrated conditioner guarantees to speed up wilting significantly even in dense crops and with short periods of fair weather – making it a firmly established link in the harvest chain on many farms where top forage quality counts.

The new DISCO 9300 C AUTO SWATHER is approved for tractors with outputs of over 400 hp and offers even greater wear protection while at the same time reducing the weight.

Stronger drive, maximum wear protection and even greater comfort

The new drive train in the new DISCO 9300 C AS offers even greater throughput and operational reliability – with approval for tractors with outputs of over 400 hp. The use of high-quality Hardox components on the conditioner has further improved wear protection and at the same time reduced weight. The design of the cross conveyor belts has been optimised by switching to laser welding to reduce weight and fitting four lower supports to the AUTO SWATHER belt units to maximise stability in continuous use with heavy crops. New drive rollers for the cross conveyor belts have reduced the noise level significantly – a real bonus for operator comfort. More clearance for mounting to the tractor and a completely new stand design make mower attachment and removal even easier and enable space-saving, yet safe storage of the mower in folded position.

Further arguments in favour of the DISCO 9300 C AUTO SWATHER: Compact for transport and storage, safe and convenient for attachment and removal.

Smart Mowing: automation for multiple applications

The intelligent control concept enables the front mower controls to be integrated into the ISOBUS of the rear combination, or the whole mower combination to be operated via the tractor’s headland management system – whichever the operator prefers. Furthermore, the DISCO 9300 C AS offers unique comfort features such as automatic BELT BOOST acceleration to clear the belt units at the headland, automatic belt speed reduction for one-sided lifting and automatic lifting of the mower units when shifting to reverse. The optional CLAAS automatic slope control regulates the belt speed and ground pressure when working on slopes to ensure optimum swath formation and sward protection while minimising drift.

Leading the field for decades: proven DISCO genetics for maximum productivity

As with all DISCO mowers, the proven MAX CUT mower bed with quick-knife change and ACTIVE FLOAT suspension are responsible for the outstanding cutting performance. For decades these features have stood for clean forage, maximum sward protection and high capacity combined with high cutting frequency at a PTO speed of only 850 for optimum efficiency. Measurements at Kiel University of Applied Science have confirmed an average fuel saving of 22 percent. For high-volume mowing operations with the DISCO 9300 C AS, this equates to a saving of 6 to 7 l per hour.

The new flow-optimised wear skids for a 7 to 9 cm cut height reduce crude ash contamination and accelerate regrowth. This feature also reduces tractive power requirement and diesel consumption.

MAX CUT stands not just for top forage quality and efficiency, but ultimate reliability and durability as well. So all mowing discs are equipped with four wear protection studs as standard for a double service life. All knife holders have a high-quality tungsten carbide coating on the underside, something normally seen only in tillage implements.

As with all DISCO large-scale mowers, the side arms are equipped with mechanical or hydraulic non-stop collision protection with a particularly robust pivot point. When the mower encounters an obstacle, the arm swings back and over it – moving the mower unit as far from the danger zone as possible.

Key features of the DISCO 9300 C AUTO SWATHER at a glance:

- Efficient, high-capacity mower for all crops with conditioner and swath grouping

- 9.10 m working width.

- New heavy-duty drive train for tractors over 400 hp

- Hardox-reinforced conditioner plates for increased resistance and longer service life.

- New, laser-welded swath belt frame: lighter, yet even more robust.

- Swath units supported at four points, optimised centre of gravity when folded over the mower bed during full-width deposition.

- More ribs on the drive rollers of the conveyor belts significantly reduce noise.

- Arms positioned further from the rear tractor wheels and new rear support feet for convenient attachment and removal.

- SMART MOWING with a wide range of ISOBUS comfort functions and automatic slope control for maximum operator comfort and performance even on slopes.

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.