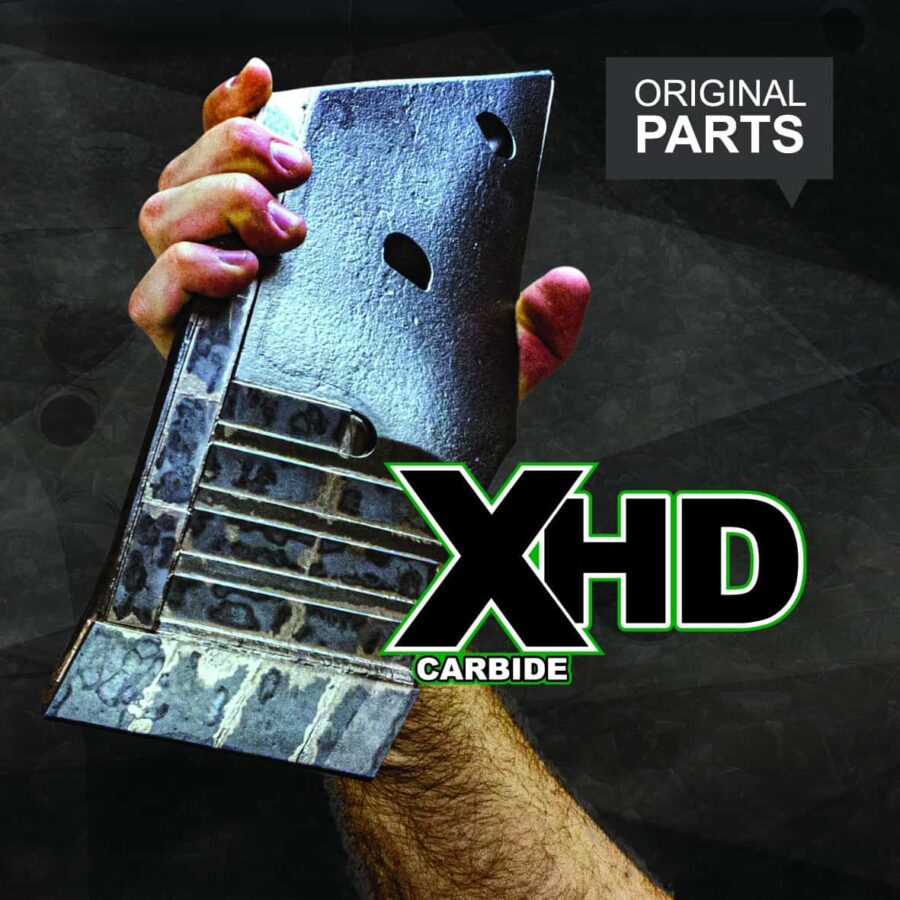

A new range of tungsten carbide-tipped parts has been developed by Kverneland for use on its ploughs and power harrows.

Called XHD Carbide, these extra heavy-duty components incorporate a new design of tungsten carbide tile, that wraps around the leading edge of parts. This corner tile design prevents the hard-wearing elements from being damaged or knocked off by hidden obstructions, when leading edges are put to work.

Corner tiles complement the existing straight tile design, which is now used on flat-faces for extra protection, leaving the advanced corner tile design for use on high-pressure leading edges.

For ploughs, the extended range of carbide-tipped components now joins the plough point, and includes short and long landsides, shins and skimmer shares. For power harrows, extra protection comes from wrapping the leading edge of the tine with a tungsten carbide tile.

“We’re extremely excited about this new range of XHD original parts,” says Richard Bennett, Kverneland parts marketing manager. “The base metal on all XHD parts receive the same heat-treatment and toughness processes as all other Kverneland original parts, but with the addition of tungsten carbide tiles.”