The new AXOS 230 and 240 offer a host of different technical features relating to performance, power transmission, comfort and payload to suit different customer specifications and fields of application. The specification includes power outputs of 92 and 103 hp, a 5-speed powershift transmission with REVERSHIFT and TWINSHIFT, wheel sizes up to 34-inches, a gross vehicle weight 6.0 t and a flat floor with a comfortable command centre.

Fitting in below the ARION 400 range, the AXOS 200 is a sturdy, capable yet compact all-rounder that performs well even on challenging terrain, in arable and vegetable crops or forestry. With a height of 2.62 m, it can also pass through low entrances and is astonishingly agile thanks to a minimum turning radius of 3.79 m.

Four-cylinder power from FPT: powerful, efficient and low-maintenance

Power for the AXOS 200 range comes from state-of-the-art FPT four-cylinder turbo engines with common-rail injection and Stage V emissions standard. The 3.6 l engine features 1800 bar injection pressure, wastegate turbocharger, intercooler and viscous fan, with maximum power output at 2000 rpm. Maximum torque on the AXOS 230 is 366, rising to 406 Nm for the 240. Full engine torque is available across a wide speed range.

The fuel tank capacity is 105 l and in addition to that is the 10 l urea tank (AdBlue) for the exhaust gas aftertreatment system. The Stage V exhaust gas cleaning system features an SCR catalytic converter, diesel particulate filter (DPF), diesel oxidation catalytic converter (DOC) and externally cooled exhaust gas recirculation (EGR). All components are housed beneath the bonnet outside the driver’s field of vision. The slender exhaust pipe fits perfectly in front of the left A-pillar without impairing visibility, and without compromising the low, narrow bonnet design. Alternatively, the exhaust pipe can be integrated between the right-hand step and the front console where it is well protected. Despite the integrated exhaust gas aftertreatment system, the engine area remains exceptionally maintenance friendly.

Instead of one engine speed memory, a version with two engine speed memories is optionally available. This is particularly useful when working with PTO-driven or hydraulically operated implements. After saving the engine speed using either the foot or hand throttle and pushbutton, subsequent adjustments can be made with two pushbuttons.

Always at the right speed: flexible working from 500 m/h to 40 km/h

The 5-speed transmission in the AXOS 200 provides 30 forward and 15 reverse gears, with as many as 10 gears in the main operating range and a short shift lever for easy car-like shifting. TWINSHIFT powershift transmission – which increases tractive power by 20 per cent at the press of a button – and the electrohydraulic REVERSHIFT clutchless reverser are included as standard. Another comfort feature that is normally associated with large tractors is the clutch button on the back of the shift lever – which eliminates the use of the foot clutch in virtually all operations, especially road journeys – and the optional SMART STOP function, which automatically disengages the transmission to bring the tractor to a standstill when the foot brake is applied at traffic lights, junctions and during front loader work and re-engages it when the foot brake is released. These transmissions reach a top speed of 40 km/h at just 1750 rpm.

From tractor to implement carrier

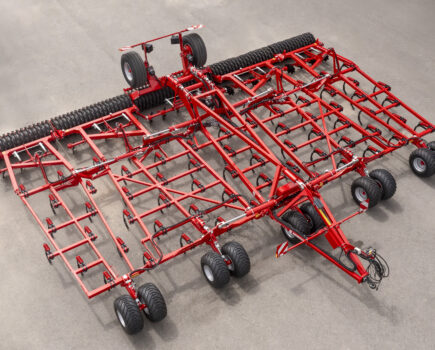

With a lift capacity of 3350 kg, the AXOS 200 easily handle standard cultivation or grass management implements and grounds maintenance equipment. Both models can also be optionally fitted with a front loader with a lift capacity of 3200 kg – more than enough for front-mounted attachments. The AXOS 200 has an open-centre hydraulic system with an output of 87 l/min as standard, with an optional third pump available to increase output to 114 l/min. For this, the AXOS 200 can be supplied with an electrohydraulic operating system with ELECTROPILOT and rocker switches as an alternative to the standard mechanical version. At the rear, up to three double-acting spool valves and a free-flow return line are available, while a fourth double-acting spool valve is available with the third pump option. In addition, AXOS can be fitted with two mid-mount double-acting connections for use with front loaders.

The PTO specification is equally impressive: as an alternative to the 1000/540, the AXOS 200 can be equipped with the 540/540E combination and a ground-speed PTO can also be supplied as an option. Furthermore, a front PTO with 1000 rpm or 540E is available for the front linkage. The electrohydraulic PTO coupling guarantees a smooth start and protects the PTO transmission, drive shaft and drivetrain.

A perfect fit: five front loaders for every situation

Tailor-made front loaders from the CLAAS range make the AXOS 200 even more versatile. AXOS 200 tractors can be fitted with the larger FL 80 series (hydraulic self-levelling linkage) and the FL 80 C series (mechanical self-levelling linkage), in addition to the FL 60 front loader with PCH hydraulic self-levelling linkage and the FL C 40 / 60 and FL E 40 / 60 series with mechanical self-levelling linkage. The front loader brackets are positioned well back, providing stability during heavy work. The robust bolted connection between the front loader bracket, made from high-strength cast steel, and the engine half frame does not compromise the steering lock or ease of maintenance.

The FITLOCK system and MACH quick-attachment couplers for electrical and hydraulic connections make short work of attachment and removal. Changing attachments on the front loader is also quick and easy with FASTLOCK and SPEEDLINK. The SHOCK ELIMINATOR vibration damping system is supplied as standard with all front loader models.

There is a choice of two operating systems for the front loader; the E-PILOT S or the ELECTROPILOT, both within easy reach in the right-hand console. While the E-PILOT S provides fingertip control of front loader functions only, the ELECTROPILOT can also be used to operate hydraulic functions on rear implements. In addition, instead of using the lever on the left of the steering column to change direction, the REVERSHIFT reverser can be operated using two pushbuttons on the ELECTROPILOT. This means that all relevant functions for front loader work can be controlled single-handedly.

Stay focused and relaxed: cab with ergonomic side console, air conditioning and air-suspended seat

The left-hand door opens wide to enable driver and passenger to step into and out of the flat-floor cab safely and comfortably. Air conditioning and an air-suspended driver’s seat are optionally available. Slender pillars for an excellent all-round view are supplied as standard, while the curved rear windscreen gives a particularly clear view to the rear. Both front and rear windscreens can be opened. For greater safety, CLAAS can optionally supply an additional rear-view mirror for the cab interior.

The passenger seat on the left-hand side is also supplied as standard and can be folded away to save space when not in use. The height and angle of the steering wheel can be adjusted to suit every driver.

The main controls are located in the ergonomic side console, grouped according to function and all within easy reach. Shelves and storage areas can be found on and beside the side console. All relevant information such as diesel consumption per hour, transmission oil temperature or fill level of the diesel particulate filter can be viewed on the 4.2-inch colour display in the steering wheel console. The display can also be used to adjust the settings of functions such as rear linkage lift speed, and for versions with electronic spool valves, the response time of the hydraulic spool valves and the maximum flow rate, as well as the timer.