Claydon, the European market leader in direct drilling technology with its Opti-Till® crop establishment system, will exhibit three new products at LAMMA 2025 (NEC, Birmingham, 15-16 January 2025). The Claydon stand (Number 6.600) will include the company’s new Evolution Front Hopper, a 4m version of its Evolution Drill Toolbar with twin-tine fertiliser placement, and a Claydon Mole Drainer. Claydon will also exhibit a 6m T6 Hybrid trailed drill, a 3m M3F Evolution mounted drill with grain and fertiliser, and a 9m Straw Harrow.

David Furber, Claydon’s Sales Manager for the UK and ROI, states: “We will use LAMMA 2025 to promote the new Claydon Evolution Drill Toolbar and Evolution Front Hopper, showcasing our ability to offer flexible seed/fertiliser placement, meeting the requirements of the Sustainable Farming Incentive (SFI) schemes and growing companion crops. The fact that also we have this option available on our 3m M3F Evolution and 6m T6 trailed drills demonstrates how we can offer farmers the option of generating additional income through the SFI, with ideal seed placement.”

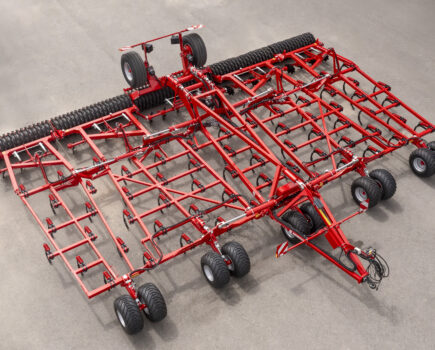

The Evolution Drill Toolbar can be used in conjunction with the Evolution Front Hopper and is available in widths of 3m, 4m, 4.5m, 4.8m, 5m or 6m. The standard specification includes one distribution head with 38mm seed delivery hoses, but a second distribution head can be optioned, allowing fertiliser to be supplied to either the front leading tine or rear seeding tine.

With a total capacity of 2750 litres, split 45/55%, the Evolution Front Hopper is pressurised to ensure reliable high-volume material delivery to the rear distribution heads. Twin metering units deliver either mixed or separated seed/fertiliser flows to the rear-mounted drill, a simple airline box selector diverting the flow of material to the distribution pipes or combining the total output into one pipe. An ISOCAN terminal controls all front hopper functions and allows variable rate seeding, depending on the task controller and licence key.

ISOBUS compatible, the Evolution Front Hopper is supplied with small, medium or large diameter interchangeable metering wheels to suit a wide range of seeds and fertilisers. Weighing 730kg, it measures 2476mm wide, 1803mm high and 1619mm long, incorporates two hopper sensors providing ‘low level’ and ‘empty’ warnings, work lights, two road vision cameras, a toolbox and foldable front footstep. Options include 550kg of ballast, plus packer wheels with passive steering and wheel scrapers.

The single-leg Claydon Mole Drainer combines the benefits of mounted and trailed designs without the drawbacks of either, enabling mole drains to be formed easily and accurately. The user-friendly design means that it is easy to adjust and even on very heavy land can be handled by a well-ballasted 200hp tractor.

Mounted on the tractor’s rear three-point linkage the implement features a long, narrow beam which allows the 75mm-diameter mole bullet and following 100mm ceramic expander to run parallel to it, producing a uniform, stable channel at the correct depth and angle. The design also avoids excessive friction between the beam and soil surface, minimising draft requirement and fuel use.

The unique oscillating headstock features a swivel joint which makes the Claydon Mole Drainer extremely easy to manoeuvre and allows it to reach further into headland ditches or over drains. Because the narrow beam is held in the upright position there is no need for outrunner skids and the angle of the bullet can be precisely adjusted. Locked in place by a steel wedge, the blade pivots on three pins and the bullet angle is controlled by the narrow 200mm-wide front skid, allowing mole draining through standing crops with little damage.

Chains linking the oscillating headstock to the beam allow the tractor to turn easily and progressively lift the beam, enabling the mole to ski out of the ground gently with minimal soil disturbance.

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.