Bale preservative application specialist Harvest Tec has announced the establishment of its own dedicated UK and Europe sales and service support network for its applicator range and Baler’s Choice preservative.

The change in distribution arrangements has been made to enable Harvest Tec to have direct control over the levels of service and support for its products, while meeting customer expectations over initial availability of application systems when sold and ongoing technical and spare parts support.

Based in Hudson, Wisconsin, Harvest Tec is a leading manufacturer of advanced manual and automated preservative application systems and moisture sensors, suitable for applying Baler’s Choice buffered preservative to hay and straw with all makes of conventional, round and large square balers.

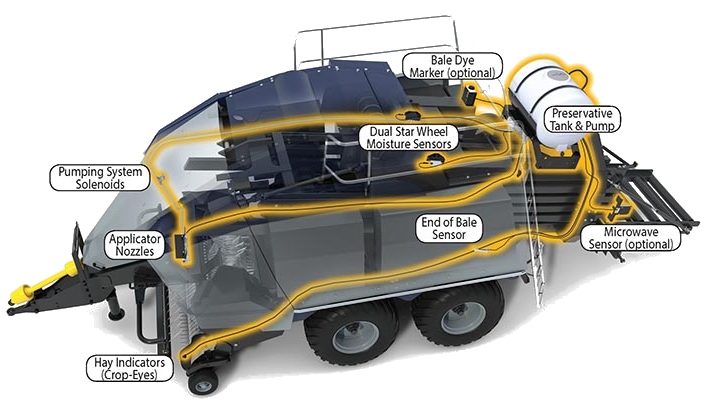

Harvest Tec applicator systems range from simple, straightforward applicators with manual rate setting, through to advanced, automated applicators that monitor both baler throughput and real time moisture content of the hay or straw as it passes through the baler to automatically adjust the application rate accordingly.

Single Harvest Tec brand

For simplicity and clarity, all applicator systems will in future be branded and supplied under the Harvest Tec name. Previously for the UK market they were marketed by OEM brand, such as Crop Saver, Thirty Plus or Hayboss, which complicated stocking and parts supply. By branding all applicators under the Harvest Tec name, this will aid both applicator and spare parts availability, and help reduce cost.

To ensure prompt availability of applicator systems and the rapid supply of spare parts throughout the UK, Harvest Tec will be working with Carr’s Billington, who in addition to handling sales within their own area, will also act as a central distribution hub for Harvest Tec, holding both applicator units and spare parts for dispatch to all other Harvest Tec UK dealerships.

“Harvest Tec is excited to transition our UK distribution of applicators and moisture sensors working with Carr’s Billington to allow us to better serve the UK dealer network and provide on-time delivery to customer requests,” comments Bryant Henningfeld, Sales Manager for Harvest Tec Inc. “We are committed to serving the livestock and equine markets by extending operator baling time as well as producing superior quality hay and straw, and this new distribution model will provide superior product availability and precision application equipment in order to achieve that.”

Baler’s Choice preservative

All Harvest Tec applicators are designed specifically for use with the company’s market leading Baler’s Choice, buffered Ph neutral, preservative. As previously, this will continue to be manufactured under licence and supplied by the agricultural division of Monarch Chemicals Ltd.

The core ingredient within Baler’s Choice is a near neutral, buffered form of Propionic Acid. This retains all the well recognised and proven benefits in reducing heating and stabilising temperature within bales, in addition to the prevention of moulds, dust and loss of bale quality. But being near neutral Ph, it avoids damage to the baler and is safe to handle. This is combined with Citric Acid to aid colour retention and palatability.

When applied at the correct rate, Baler’s Choice enables hay to be baled at moisture contents between 16% up to as high as 30%. Between 16-22% moisture, untreated hay will start to discolour and smell musty. At between 22-26%, bale temperatures can start to rise rapidly to as high as 120 deg F with the risk of spontaneous combustion, and mould will develop so reducing hay quality. Above 26% hay quality will be severely reduced and the fire risk considerable.

By applying Baler’s Choice, not only are these risks avoided, but operationally by not having to wait until hay in the field is below the optimum 15% MC, it enables baling to start earlier and finish later in the day, so optimising baler use and daily output. Baler’s Choice also avoids the risk of damper crop within the field or from under trees, affecting bale quality. In addition, the cost of additional tedding is avoided and ultimately because hay quality and feed value is retained, this will aid livestock growth rates or if sold, treated hay that smells fresh and looks bright and green will always be attractive to the end user.

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.