CLAAS is celebrating half a million combine harvesters built since 1936 – and is producing several anniversary machines from LEXION, TRION, EVION and DOMINATOR at three locations on three continents. These will be on display at trade fairs, field days and demonstrations in the coming weeks and months.

European pioneer of combine harvester production

CLAAS has been one of the key pacesetters in combine harvester development for many decades. From 1936 onwards, the Harsewinkel/Germany-based family company rationalized grain harvesting in Europe with the mowing-threshing-binder with the cross-flow principle, or M.D.B. for short. The great success finally came in 1946 with the SUPER series, which from 1953 could also be delivered with add-on engines and from 1958 as the SUPER AUTOMATIC with a hydraulic cutting unit drive. More than 60,000 units of the SUPER were marketed worldwide and even found buyers in Canada and Uruguay.

In 1953, the family company successfully entered the self-propelled combine harvester segment with the HERCULES, which was later renamed SF. In 1961, the MATADOR GIGANT set new standards with a cutting bar width of up to 6.0 m. Other industry-defining milestones of the 1960s included well-known names such as SENATOR, COMET, COSMOS, CORSAR, MERCATOR, PROTECTOR and COMPACT.

In 1972, the DOMINATOR series opened a new era that has lasted more than 50 years to this day. CLAAS consolidated its status as the European market leader, particularly with the DOMINATOR 6 and DOMINATOR 8 series, and introduced innovations such as 3D cleaning, the AUTO CONTOUR cutting unit guidance and the MEGA threshing unit. The DOMINATOR CS with cylinder separation (commandor CS from 1986) presented in 1981 were among the most powerful combine harvesters in the world at the time, and were first delivered with rubber tracks from 1987 onwards.

At Agritechnica 1995, the LEXION 480 with groundbreaking APS hybrid technology was not only the highlight of the trade fair, but also a game changer in terms of performance, comfort and groundbreaking electronic applications for the emerging precision farming era. Since 1997, the ground-protecting TERRA TRAC chassis technology on the LEXION – also available for the TRION since 2021 – has been celebrating its worldwide triumph.

A huge step in the area of machine intelligence followed in 2013: With CEMOS, CLAAS has since become a leader in the field of combine harvester automation, which has been underpinned by numerous international awards. CEMOS continues to be continuously developed and expanded to include additional processes and units in combine harvesters and attachments.

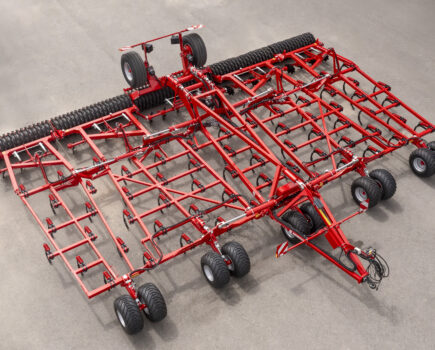

The latest members of the CLAAS combine harvester family are the TRION and EVION series presented in 2021 and 2023. Together with the LEXION, they offer a unique range of products and equipment from the 205 hp five-walker to the 790 hp flagship LEXION 8900 TERRA TRAC with APS SYNFLOW HYBRID. All three series enable a further increase in threshing efficiency thanks to the DYNAMIC POWE engine management system and expanded CEMOS functions. Depending on the requirements profile, an enormous range of cutting units are available – from the conventional auger cutting unit to ultra-modern, automated VARIO cutting units through to the CONVIO FLEX Draper with a flexible knife bar and flip-over reel control.

More than 500,000 success stories:

A strong foundation of experience and future readyness

With around 100,000 and more than 75,000 units respectively, DOMINATOR and LEXION account for the largest share of the 500,000 CLAAS combine harvesters built to date. SUPER and SUPER AUTOMATIC (approx. 65,000 units) as well as EUROPA and COLUMBUS (together approx. 60,000 combine harvesters) and the TUCANO (approx. 35,000 units) also contributed significant numbers to the global success of the CLAAS combine harvesters. But series built in smaller numbers, such as the COMMANDOR TERRA TRAC, were also drivers of progress and have had a significant impact on the genetics of today’s CLAAS combine harvesters. Features such as the distinctive multi-crop suitability, the undisputed harvest performance and the unparalleled efficiency have been continuously optimized over decades of development work for the benefit of customers all over the world and are deeply anchored in the DNA of every new CLAAS combine harvester. However, CLAAS combine harvesters are ideally prepared for the future not only through these strong arguments, but also through industry-leading automation and a new level of connectivity.

International competence and production network

Over the decades, CLAAS has also supplied other manufacturers with combine harvesters. Since 1992, CLAAS combine harvesters have no longer been manufactured exclusively at the Harsewinkel headquarters. That year, the first CLAAS CROP TIGER rolled off the assembly line in India, of which more than 10,000 units have been produced. Since 2001, CLAAS has also been producing LEXION hybrid combine harvesters for the North American market in its own factory in Omaha – in colored yellow and with Caterpillar branding until 2019.

Since 2013, following the takeover of Jinyee, CLAAS has also been producing combine harvesters and combine harvester components in China. The new DOMINATOR 370 hybrid combine was introduced here in 2019, followed three years later by the DOMINATOR 260 with six walkers. The new EVION, which, like the DOMINATOR 370 and 260, was developed in Harsewinkel, has also been rolling off the production line in Gaomi since 2023.

As another location in the combine harvester competence network, Törökszentmiklós in the south of Hungary has been producing cutters and corn pickers for CLAAS combine harvesters since 1997. In October 2021, the 100,000th cutting unit for CLAAS was celebrated here.

Automation, assistance and data management:

From the Throughput Control Device to CEMOS and CLAAS connect

The fact that threshing performance has increased since the first European combine harvester, the MDB, is not only due to further developments in hardware and higher engine performance. Over the last 25 years in particular, automation has become an increasingly important part of further optimization in the areas of efficiency, productivity and work results. With the introduction of the throughput control device in 1974, CLAAS began integrating electronic operating aids into combine harvesters. The CEMOS, which was introduced in 2013 and has since won several awards at international trade fairs such as Agritechnica and SIMA, then proved to be a real game changer: to this day, it has been continuously expanded to include further processes in the combine harvester and on the cutting unit, enabling optimal utilization of the machine with a full focus on maximum harvesting performance – supported thanks to the unique multi-crop suitability of all CLAAS combine harvesters.

CLAAS was also one of the pioneers in combine harvester construction for precision farming applications. From 1991, yield data and GPS position data could be linked with one another – and from 1996, the LEXION even offered yield mapping via AGROCOM MAP followed in 1998 by telemetry-based fleet management via Combine Online. In 2005, LEXION combine harvesters were the first CLAAS products to be equipped with the groundbreaking TELEMATICS. From October 2024, the digital networking of CLAAS combine harvesters with the rest of the fleet, operations management and the CLAAS service and sales partner will take place in the new CLAAS connect, opening a new chapter in the area of digital machine and farm management.

More than a machine: The CLAAS principle

From the first combine harvester in 1936 until today, CLAAS has provided its customers with comprehensive support. When purchasing a combine harvester from CLAAS, customers expect maximum performance and productivity through leading technology and optimal support. With a user-friendly operating concept, groundbreaking driver assistance and close networking with the CLAAS service partner, not only is maximum campaign performance achieved, but also a unique lifetime performance of every CLAAS combine harvester. It is thanks to this future viability that CLAAS combine harvesters have always remained in use for a very long time – in some cases for more than five decades. Due to extremely low annual losses in value, all CLAAS combine harvester series and models are very popular, even when used.

Modern driving assistance systems such as CEMIS and GPS PILOT are just as important today as the CLAAS MAXI CARE maintenance contracts. And thanks to the wide range of attachments and low effort required to change between crop types, CLAAS combine harvesters are ideally equipped for every application. Because when harvesting, speed, versatility and variability are required – as well as the highest level of reliability.

These characteristics are united in all CLAAS combine harvesters and have been so for 500,000 success stories. It is this experience from almost 90 years of combine harvester production that makes “Made by CLAAS” a promise.

To mark the anniversary, a limited number of EVION, TRION and LEXION were built in a special paint finish and with extensive decals. A DOMINATOR in the corresponding design will be on display at the CIAME in China.

Anniversary machines for demonstrations and trade fairs – Sales Edition for customers

In order to underline CLAAS’s global combine harvester production network and to allow all locations to participate equally in the anniversary, several anniversary machines have been and are being built with a special look. The LEXION, TRION, EVION and DOMINATOR will be on display at various national and international trade fairs as well as at field days and in demo use in the coming weeks and months. The design is a homage to the CLAAS combine harvester product history: The silver metallic color represents the beginnings of CLAAS combine harvester production up to 1961, the seed green metallic represents the well-known CLAAS color scheme introduced in 1966 with the SENATOR. Knotting pattern in the CLAAS letters on both sides of the anniversary machines reference the old CLAAS shape logo with the CLAAS knotter hook – the first CLAAS patent from 1921.

“500,000 CLAAS combine harvesters are, above all, 500,000 success stories, because farmers and contractors worldwide have placed their trust in us 500,000 times,” explained Jan-Hendrik Mohr, CLAAS CEO. “We are therefore celebrating this unit anniversary internationally with a global roll-out of several anniversary machines in Harsewinkel, Omaha and Gaomi. This also reflects and appreciates our international competence and production network for combine harvesters, which of course also includes our production site for cutterbars and corn pickers in Törökszentmiklos, Hungary.”

For the 2025 harvest season, customers can order a sales variant with an anniversary silhouette on the side flaps and special feature packages.

Customers can participate in the anniversary for the 2025 harvest season with a special sales edition, which, in addition to selected equipment features, is characterised by “More than a machine” stickers on the side panels. All CLAAS combine harvesters from the 2025 product year will also receive a small sticker on the cabin door. “A CLAAS combine harvester is actually much more than a machine,” continued Mohr. “Because behind every EVION, TRION, LEXION and DOMINATOR there is a powerful sales organisation, highly professional service, fast and reliable spare parts supply and much more. And last but not least, a strong international marketing of used machines, which, like the technical factors of overall performance, reliability and durability, inspires customers all over the world.”

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.