In recent years farming machinery has evolved significantly. Technologically advanced tractors have been leading the drive towards precision farming, a move to improve performance and efficiency in farming using intelligent devices.

On the contrary, trailers have remained far away from this technological revolution and represent a bottleneck to this market transformation.

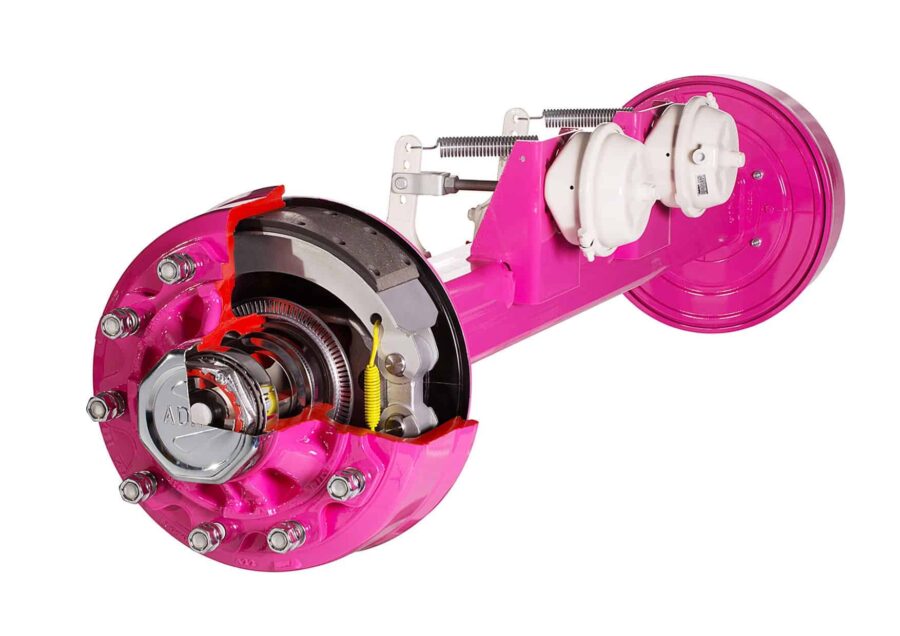

In particular, farming trailers consist in vehicles connected to tractors for the carriage of loads, made up by a cargo bed placed on two or more axles. The axle can be described roughly as a beam with wheels connected to its extremities.

The axles have historically had limited or no intelligence associated with them. This is restricting the scale of benefits of innovation in other equipment and leading to unnecessary maintenance and unexpected failures. To address this issue, major influencers in the agricultural machinery market in Europe have come together to develop a new generation of higher performing and intelligent axles: the TEKNOAX 2.0.

The new axles alert the user when maintenance is needed by monitoring performance and working conditions, thereby helping to optimize maintenance intervals and associated costs. The intelligent axles also include an inflating / deflating system so that tyres can be automatically adjusted to working conditions. This helps to improve trailer performance on-road and on-field, increase life cycles and further reducing operating costs. Indeed, the project to develop these smart units and deliver them to market has the potential to increase farming efficiency and push precision farming to the next level.

TEKNOAX 2.0, has been coordinated by ADR SpA, an innovative axle manufacturer based in Italy. Other partners are COLAERT Essieux, a French suspension manufacturer that specializes in adaption and customisation of axles for ‘on field’ testing; RINA, one of the leading Italian engineering companies and one of the top EU certification organisations, and FARMTECH d.o.o., a Slovenian manufacturer of trailers and spreaders that will work to validate the new axles in real working conditions through a pool of end users throughout Europe.

RINA has experience in the design of intelligent systems, control units, communication systems and collaborative platforms. The new ADR axles have been developed with enhanced mechanical properties for increased reliability. These have been equipped with a communication system which connects to a collaborative platform, both developed by RINA, to track performance and maintenance of each unit. COLAERT has implemented the system on trailers and carried out a first phase of testing on-road and on-field in close collaboration with RINA and ADR. The intelligent axles have undergone a final stage of validation in real-world working conditions in tests coordinated by FARMTECH trailer end-users throughout Europe.

New sensing capability and the communication system on the next generation axles allow to monitor trailer weight, usage and identify any misuse. Such features assist with new business models for trailer rentals, whereby accurate usage and misuse can be clearly identified.

The new axles will also realise the potential for new business models such as trailer renting and trailer sharing, easing the approach to farming for young entrepreneurs and start-ups.

Giannicola Loriga, head of corporate R&D technical coordination at RINA said: “This was an exciting project that will bring axles and trailers more in line with the precision farming revolution. The four companies involved are leaders in their fields of expertise and made a strong partnership and were very committed to this project and to the launch of new products and services in the agriculture industry.”

The TEKNOAX 2.0 project has been funded from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 737848.