The 2.5m Grassland Loosener Lite (GLL Lite), which reduces soil compaction while protecting the surface of the field, has been specifically designed for use with lower horsepower tractors.

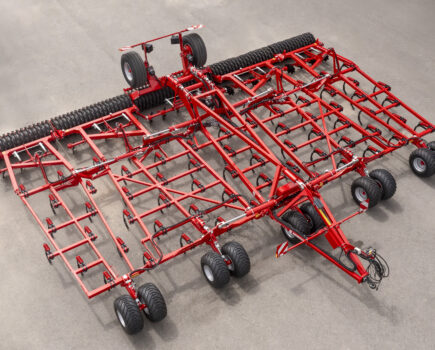

The new implement is based on Grange’s popular 3m Grassland Loosener but is built on a more compact scale to accommodate tighter spaces and smaller tractors.

Available with three or four front discs and low disturbance loosening tines, it is aimed at livestock farmers and those running mixed farms, but is also likely to prove popular with growers who direct drill wanting to lift and loosen the soil structure without creating another pass before drilling.

Rhun Jones, Managing Director of Grange Machinery, said the GLL Lite is an innovative and versatile machine designed to fill a gap in the market.

He said: “We’re launching the GLL Lite due to demand from farmers for a compact grass loosener suitable for pasture and grazing land.

“Whereas a lot of farmers really liked our 3m Grassland Loosener – which was the template for the GLL Lite – they wanted something that was easier to pull.

“Early feedback from testing has been extremely positive.

“By alleviating soil compaction and shattering and removing the plough plan, root development is significantly enhanced, more air can reach the crop roots, and drainage issues are resolved, leading to healthier, higher yield pastures.

“Thanks to our low disturbance legs and points, which provide a full width lift with minimal surface disturbance, it is able to achieve all this while ensuring the precious swards are protected.”

The GLL Lite is available with three or four front cutting discs which enhance the loosening element of the leg and eliminate surface tension.

This reduces the potential for soil boiling in front of the leg and eases the flow of trash through the machine.

Options include either Shear Bolt or Hydraulic Reset Protection, an LED Road lighting kit and a 2.5m Toothed Packer Roller.

Rhun added the GLL Lite was further proof of Grange Machinery’s ability to provide the innovative solutions that the market demands.

“We listened to what farmers wanted, designed it, and have put it into production in a very short period of time,” he said.

“It’s an extremely versatile piece of kit and we’re very excited to be launching it at Cereals 2025.”

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.