A groundbreaking project aimed at utilising unused broccoli to reduce the CO2 footprint and environmental harm of protein for human consumption is underway thanks to a partnership between the UK Agri-Tech Centre, Upcycled Plant Protein (UPP) and The James Hutton Institute (JHI).

The project, ‘SusProt: Sustainable Plant Protein from Vegetable Crop Sidestreams’, aims to solve two of the world’s food related challenges; where sustainable alternatives to animal derived protein will come from and addressing issues with farm labour and food security.

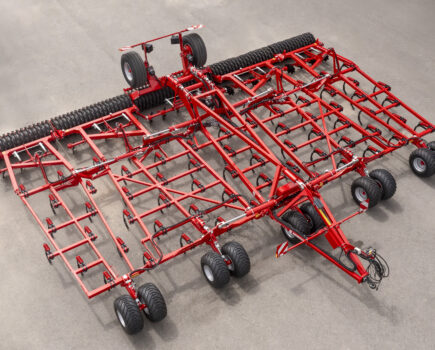

The automated broccoli harvester uses computer vision and machine learning to identify broccoli heads that are ready to be harvested. Then, instead of harvesting only the heads of the broccoli, the whole plant is cut by a patent-protected harvester. Parts of the plant that are currently unused are then turned into high-protein hypoallergenic ingredients for use in food products, which could include meat alternatives or ‘hybrid’ (reduced meat) products.

What’s the problem?

Due to labour shortages, often the British broccoli farmer cannot harvest all that they grow, resulting in waste. Reduced labour mobility, rising wages and adverse weathers, all make manual harvesting an untenable answer to getting the crop from the field to the packhouse. As importantly, labour rate inflation is a major driver of increasing farmgate costs, that are then passed on the consumer.

Allergies and intolerances to existing plant proteins are an issue for some consumers, and shoppers are increasingly seeking an alternative plant-based protein to soy, wheat and pea that satisfy a more balanced set of health, palatability and environmental credentials. Specifically, production of soy, a major non-meat protein, can create issues with biodiversity, water resources, deforestation and soil erosion in Brazil, Argentina where much of it is grown – as well as significant ‘food miles’ when consumed in the UK.

What’s the opportunity for ‘UK PLC’?

The shift from animal to plant-based diets has only just begun and an increasing awareness of the environmental impacts of existing plant-based protein ingredients is creating a need in the market. This project aims to deliver sustainable, hypoallergenic plant-based protein with the ‘health-halo’ of broccoli.

Mark Evans, CEO at Upcycled Plant Protein, said: “External validation of the nutritional composition and environmental harm reduction is extremely important in giving an early-stage company the credibility needed to work with the UK’s leading food manufacturers, and working with the UK Agri-Tech Centre and the JHI has been important in achieving this.

“In addition, getting the farmers’ perspective of what the technology needs to achieve is extremely important and we have been fortunate to have received some fantastic input from the agricultural community as to how we can help them address their business issues.”

What’s the solution?

The project aims to enable farmers to overcome key challenges of harvest labour availability and offers the prospect of improved yields and better product quality using the Automated Selective Harvester, which is enabled by Machine Learning. This enabling technology builds upstream scale capacity for the production of alternative proteins and erects a barrier to entry. In addition, images of the crop are captured during harvest allowing for more granular information than has been possible before, allowing insights that will ultimately improve productivity and profitability. In aggregate, this will allow farmers to grow more, reduce waste, make a better return and potentially improve yield and quality.

Using a proprietary process, the project has delivered pilot-scale production of sustainable, palatable protein from the ~70% of the broccoli plant that is currently not being used, along with biomass that is currently un-harvested. The project aims to allow processing near where broccoli is grown – eliminating ultra-processing and transport costs.

Sue Gordon, Project Manager at the UK Agri-Tech Centre, said: “UPP has benefited from the fantastic agricultural science base of the UK by working with the JHI and leveraging UK Agri-Tech Centre’s fantastic depth of relationships within the UK ecosystem.

“This has allowed us to move quickly and reduce the capital intensity of developing a complex stack of technologies.”

Why broccoli?

Broccoli is one of the most nutritionally dense foods, scoring 100 of 100 in the Tufts University ‘Food Compass’. Broccoli protein is comparable to pea and soy in terms of the core amino acids and has no identified allergens listed in the major allergen databases. It has high digestibility and contains all the indispensable amino acids.

How does this benefit the community?

Using unused biomass to produce nutritious hypoallergenic ingredients reduces the CO2 footprint when compared for foods ‘grown for use’ such as soy. Displacing ingredients grown in the South America and the US with locally grown ingredients, reduces processing and the CO2 footprint as well as environmental harm and costs.

What’s next?

Sustainable, palatable, hypoallergenic protein can be provided in low-processed forms to allow the food manufacturer to deliver nutritious and affordable products that have low embedded food miles and reduced environmental impact. This will help food manufacturers to deliver new foods that meet the emerging consumer demand for environmentally sustainable healthy foods while meeting their regulatory needs of manufacturers and supermarkets to reduce Scope 3 CO2.

UPP has demonstrated many foods that include its natural hypoallergenic proteins including in burgers, sausages, soups, smoothies, bread, cakes, pet food and sauces, and has shown that its products can also be used as a feedstock for mycelium growth.

While UPP has demonstrated food concepts, UPP is a ‘B2B’ company that will sell to food manufacturers, and UPP does not intend to compete with its customers. The affordable, natural ingredients can be used along with meat or mycelium to allow ‘hybrid foods’ with the same taste and mouthfeel. This offers a lower-cost product that has a fraction of 1% of the GHG emissions of beef.

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.