Bridgestone’s Stephen Lamb contemplates the question, if it’s better to dual or not to, especially if we wish to reduce soil compaction and increase yields with our drilling operation.

Read more: To dual, or not to dual, that is the questionIt’s an interesting question, and one that would have not necessary been asked before the advent of IF and VF technologies came along. But it should be now challenged and well worth doing the exercise to establishing the answer.

To be clear here, we are only talking about the use of duals to enable you to drill lightly over the land, where compaction and yield are the key focus and not for any stability or consolidation requirements.

So, let’s start with your current dual drilling set-up and look at the following areas:

- Operating Pressure

- Total Tyre Width

- Load Applied

- Working Width of the implement to gain ‘Tyre to Field Percentage Contact’

Once we have these benchmarks, we can look at other potential solution improvements to the reduction in compaction and an increase in yields from the current dual fitment set-up to than of a single fitment set-up, potentially.

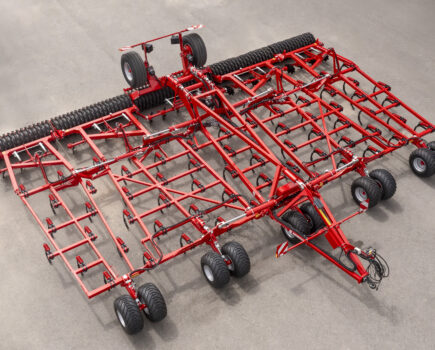

As an example of this, please see the below, where the current set-up has 4qty 650/65 R42 with a 4m trailed drill and an axle load of 6,000kg (single fitment – transport / raised).

If we were to offer, say, 2qty VF650/65 R42 as one alternative, could two tyres be better than four?

Operating pressures – With the load of the axle being 6,000kg – All tyres (load) would operate at the manufacturers lowest permissible limit of 9psi.

Total tyre width in Inches – Duals (4×25.5) = 102” Singles (2×25.5) = 51”

Load applied to the Soil – Duals 102 x 9 = 918 lbs per inch of forward travel.

Singles 51 x 9 = 459 lbs per inch of forward travel.

So, with both set-ups operating at the lowest pressure setting possible, the singles win here.

However, if there was a greater pressure differential between the two setups and/or the duals had smaller widths of tyres, then duals could well be more beneficial.

Working width of implement – 4m

Tyre to field percentage contact = Duals = 65% Singles – 32.5%

So here the duals have a much greater contact with the field, and therefore a greater area of topsoil compaction will be developed than the singles, as both operate at the same pressure.

Looking at yield loss – independent studies have shown that by having an operating pressure of some 9psi, a yield reduction of some 10% could be encountered within the wheelings. So, if we were to take a field size of say 10ha with a yield potential in (un-Trafficked area) of 10t per ha. the following would be the Yield result –

Duals (35% Un-Trafficked – 65% Trafficked)

3.5ha x 10t = 35t + 6.5ha x 9t = 58.5t Total Yield = 93.5t

Singles (67.5% Un-Trafficked – 32.5% Trafficked)

6.75ha x 10t = 67.5t + 3.25ha x 9t = 29.25t Total Yield – 96.75t

So due to the singles having a lower field contact percentage the reduction in yields from the wheelings is lower, and therefore offers a 3.25t yield improvement.

In this one example, where singles benefit from less load applied to the soil, due to less contact with the soil. Therefore, less reduction of yield loss via the wheelings, along with the additional benefitsof not having to fit and remove, nor requiring any road transport width considerations as with duals.

While this is one exercise where singles do benefit, you would need to conduct your own individual exercise to see if an alternative tyre solution specification and/or size could help or hinder your current dual set-up.

Indeed, where you have a significant differential of operating pressures and/or the total tyre width between duals and singles, then one could well outperform the other when compaction and yields are your priority.

It’s about getting the balance right between those elements. So, it’s worthy exercise to conduct in order to maximise the performance of your current set-ups.

| DUALS – 650/65 R42 vs SINGLE – VF650/65 R42 | |||||||

| 4m Trailed Drill. Axle = 6,000kg (Single fitment). | |||||||

| Pressure @ 30kph | Total Tyre Width | Total Tyre Width | Load Applied over 1 sq inch of Total Tyre Width | ||||

| DUALS | 4x | 9psi | 2600mm | 102 inches | 918 | ||

| SINGLES | 2x | 9psi | 1300mm | 51 inches | 459 | ||

| Tyres to Field % Contact | 4m Drill | ||||||

| Un-Trafficked | Trafficked | ||||||

| DUALS | 65.0% | 35.0% | 65.0% | ||||

| SINGLES | 32.5% | 67.5% | 32.5% | ||||

| Assumptions – 10ha Field – Full Yield Potential i.e., Un-Trafficked = 10Tonne per ha. | |||||||

| Yield Loss in Wheelings @ 9psi = 10% | |||||||

| Un-Trafficked | Trafficked | Total Yield | |||||

| DUALS | 3.5 @ 10 = 35T | 6.5 x 9 = 58.5T | 35 + 58.5 = 93.5T | ||||

| SINGLES | 6.75 @ 10 = 67.5T | 3.25 x 9 = 29.25T | 67.5 + 29.25 = 96.75T | ||||

| An Illustration Only | 3.25T Yield Diff. | ||||||

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.