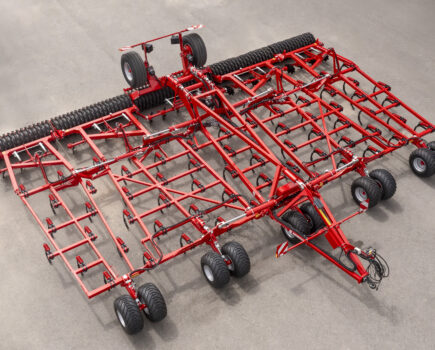

DISCO large-scale mowers from CLAAS have been making their mark in the professional forage harvesting sector on large farms and for contracting work for 25 years. Today, the CLAAS product range includes more than 15 triple mower combinations with working widths from 8.30 to 10.70 m. The five new models from CLAAS offer even more performance, greater wear protection and enhanced operator comfort to meet the exacting needs of tomorrow’s farms.

Read more: Five new DISCO large-scale mowers from CLAASDISCO 8500 C / RC TREND: agile with optimised centre of gravity

With the launch of the two new entry models – the DISCO 8500 C TREND and DISCO 8500 RC TREND – CLAAS has brought tried and tested features of the larger models to the smaller working widths. Tractors in the lower mid-range with a short wheelbase and engine outputs from 160 hp are often used in this segment, which places special requirements on the mowing equipment. When developing the new DISCO 8500 TREND, the focus therefore lay on a stable lightweight construction with a centre of gravity close to the tractor and a low rotational and tractive power requirement.

With this in mind, the basic specification includes the proven, extremely robust telescopic arm concept with optimised centre of gravity, ACTIVE FLOAT ground pressure adjustment actuated from the cab and the fast-acting mechanical non-stop collision protection whereby the arm pivots up and over obstacles before automatically resetting. In addition, the low-speed concept on the MAX CUT mower bed enables the mower to be operated at 850 rpm; the optimal, fuel-efficient torque characteristics for the tractor. On top of that, it features state-of-the-art drive technology with individual drive protection for each mowing unit and the latest bolted Walterscheid overload clutches.

Working closely with farmers and contractors, CLAAS design engineers have come up with some impressive features for the two large-scale mowers with tine conditioner (C) or roller conditioner (RC). Hardox-reinforcement of the conditioner plate has made it even more resistant to wear and stone chips while providing an additional weight saving. Doing away with the LS hydraulic blocks and hydraulic collision protection has achieved further weight savings and significantly reduced the purchase costs for this mower class. At the same time, an efficient powertrain with protection on both sides comes as standard.

Furthermore, as an option, the DISCO 8500 RC TREND with roller conditioner can be fitted with the double roller drive with innovative scissor gear unit first introduced in the DISCO 9700 RC AUTO SWATHER in 2023. This feature enables maximum throughput and service life even under demanding conditions in crops with high to very high growth.

Operation and the individual lift function are controlled conveniently and efficiently via the two tractor spool valves. Operation is even easier when integrated into the tractor’s existing headland management system.

DISCO 9300 C COMFORT and RC COMFORT: do more with less fuel

From now on, CLAAS has placed the DISCO 9300 C COMFORT and 9300 RC COMFORT above the DISCO 8500 series. Thanks to the frame with optimised centre of gravity, with arms inclined to the rear, and the low-engine speed concept with reduced PTO start-up speed of 850 rpm, it is now possible to harvest powerfully and efficiently with the added benefit of conditioning using a lighter four-cylinder tractor from 180 hp. Furthermore, the V-shaped steel tines on the DISCO 9300 C COMFORT are designed to ensure even higher throughputs at reduced fuel consumption. The new DISCO 9300 C COMFORT also features Hardox-reinforced conditioning plates for maximum durability. Conditioning intensity and deposition width are easy to adjust.

The DISCO 9300 RC COMFOR has a high-efficiency roller conditioner for harvesting alfalfa or other leafy crops like millet, which, like the new DISCO 8500 RC TREND, can be optionally equipped with the double roller drive with innovative scissor gear unit first introduced in 2023. Longer swathing plates are also available to lay the crop in the narrowest possible swath. Markets which produce large quantities of premium-quality alfalfa hay have specifically requested compact swath laying. Apart from ensuring low harvest losses, a key quality criterion here is to retain the green colour of the forage by reducing bleaching.

The new DISCO 9300 C / RC COMFORT offer exceptional operator comfort, especially in terms of hydraulic functions. The RC version is optionally available with the innovative double roller drive with scissor gear unit.

A huge advantage of the COMFORT equipment is the optional automatic control of the ACTIVE FLOAT system. When working on slopes, the ground pressure – a key factor determining forage quality, sward protection, power requirement and slope safety – can be individually adjusted on each side using the optional automatic slope system. This additional convenience eases the driver’s workload and ensures consistently high results at all times. Additional functions controlled by ISOBUS include individual lifting of the telescopic arms and optional hydraulic protective cover folding.

DISCO 1100 COMFORT: more working width and user-friendly ISOBUS operation

The new DISCO 1100 COMFORT uniquely combines a large working width with compact transport dimensions. The working width has been extended to 10.80 m by increasing the arm’s adjustment range by 10 cm. The working width can be infinitely reduced hydraulically to 9.60 m, and the two arms can be adjusted independently or synchronously. In combination with the DISCO 3600 front mower, this ensures optimal overlap at all times on tight bends or when working on slopes.

Despite the two 3.80 m wide mower units, the mower folds to a height of less than 4.00 m for road transport.

The new DISCO 1100 COMFORT with a 10.90 m working width has been added to the DISCO range in some countries.

Operation couldn’t be simpler thanks to the familiar COMFORT hydraulic controls from the DISCO 9700 and 1010; no separate control unit is needed. Lifting and lowering of the arms and adjustment of the working width are controlled hydraulically, or automatically using the programmable headland management system, while hydraulic protective cover folding and ACTIVE FLOAT ground pressure can be conveniently controlled either by the programmable F keys on the CMOTION control lever or by ISOBUS. The automatic slope control function is optionally available for convenient adjustment of ACTIVE FLOAT ground pressure and arm position.

MAX CUT: outstanding mowing performance and heavy-duty wear protection

As with all DISCO mowers, the proven MAX CUT mower bed with quick-knife change and ACTIVE FLOAT suspension are responsible for the outstanding cutting performance. Both features have proven their worth over many years and tens of thousands of DISCO mowers, delivering clean forage, maximum sward protection and outstanding capabilities combined with high cutting frequency at reduced PTO speed for optimum efficiency.

Flow-optimised wear skids for a 7 to 9 cm cut height reduce crude ash contamination and accelerate regrowth. This feature has the added benefit of further reducing tractive power requirement and diesel consumption.

MAX CUT stands for ultimate reliability and durability. So all mowing discs are equipped with four wear protection studs as standard for a double service life. All knife holders have a high-quality tungsten carbide coating on the underside, something normally seen only in tillage implements. The mower bed oil filling is designed for durability – and so reduces maintenance and costs.

Key features and innovations at a glance:

- New design with dark grey protective covers with seed green accents.

- Lubrication points with different coloured stickers indicating intervals.

- Proven MAX CUT mower bed with low-engine speed concept for maximum cutting quality with low power requirement.

- HD drives with overload protection clutches on either side of each mowing unit.

- RC model optionally fitted with double roller drive with scissor gear.

DISCO 8500 C / RC TREND:

- Two new entry-level conditioner combinations with 8.30 m working width (2 x 7 counter-rotating mower discs).

- Telescopic arm concept with optimised centre of gravity.

- ACTIVE FLOAT ground pressure adjustment from the driver’s seat.

- Fast-acting mechanical NON-STOP collision protection whereby the arm pivots up and over obstacles.

- Hardox-reinforced conditioner plates for increased resistance and longer service life.

- Optional double roller drive with scissor gear unit for RC models.

- Walterscheid drive shaft with bolted 1,500 Nm overload protection clutch.

- Direct hydraulic control with optional PLUS operation with CEMIS 10 pre-selection terminal

DISCO 9300 C / RC COMFORT:

- Two new conditioner models with 9.10 m working width (2 x 8 counter-rotating mower discs).

- Telescopic arm concept with optimised centre of gravity.

- Hardox-reinforced conditioner plates for increased resistance and longer service life.

- Fast-acting hydraulic NON-STOP collision protection whereby the arm pivots up and over obstacles.

- Longer swathing plates for particularly narrow swaths available for RC models.

- COMFORT hydraulics with direct control of arms and load-sensing operation for ACTIVE FLOAT ground pressure control, individual lift and optional folding protective covers.

DISCO 1100 COMFORT:

- Genuine 10.80 m working width (2 x 9 counter-rotating mower discs) for markets with 3.40 m front mowers.

- Hydraulic telescopic arms with wide adjustment range for optimal overlap on tight bends or slopes

- COMFORT hydraulics with direct control of arms and load-sensing operation for ACTIVE FLOAT ground pressure control.

For more like this, subscribe to the FREE Farm Machinery Buyer newsletter here and subscribe to Agricultural Trader and Farm Machinery here.