Krone launched its first KW tedder models over 25 years ago, the basic design DNA of these mounted units having been carried over to the current Vendro series. If you are after a used buy, an early model of equivalent width could, on paper, do much the same job as a factory fresh example. Subtle KW design and build tweaks, however, suggest a KW decal does not tell the full story.

Although not strictly accurate, Krone KW tractor mounted tedders broadly split into 1997 to 2007 and 2008 and on models that were replaced by the current Vendro series from 2021. In terms of basic ability all KW models will do much the same job with the caveat that Krone beefed up the build strength of 2008 models. Part of this was driven by more powerful tractors being used to operate the tedders and users working them a lot harder.

The basic specs include the factory’s recommended minimum power input for these KW units. This is more of a reminder that a tedder is not a power-hungry piece of kit. This is not to say one cannot be operated by a tractor of substantially higher power. It is not unusual to see a tractor developing north of 200hp hooked up to a nominal 8.00m working width tedder. if it is the only tractor available then that is what will get used. The problem is some will have ‘overworked’ the tedder and pre-2008 models may be more prone to wear as a result.

USED BUYER STARTING POINTS

Obviously, you need to consider working width. Krone prints a table in the rear of its sales literature that will help establish the suitability of a given model to match the widths of different mowing set ups.

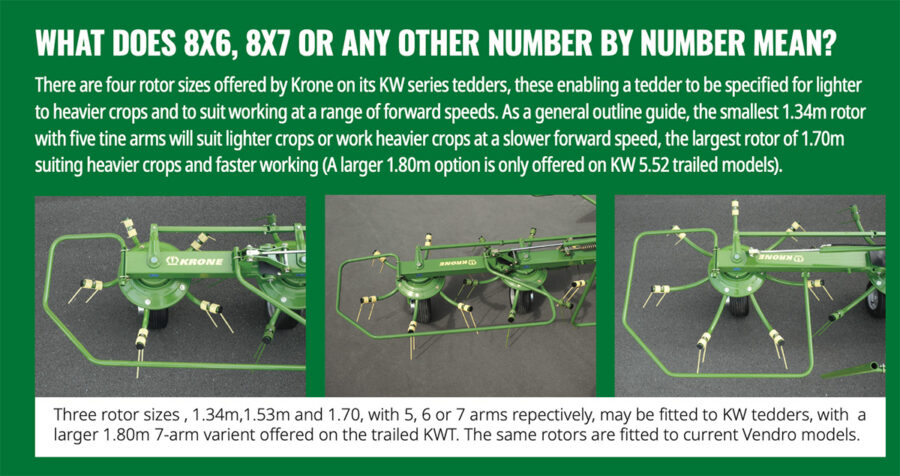

A side point is the size of rotor and the related number of tine arms. As a used buyer, you will obviously be restricted to what is available, but for the main the key stat is working width. The popular ‘second generation’ 7.82m KW7.82 /6×7 will spread three 3.0m mown rows in a pass. The model number indicates the working width, the second element indicating rotor and tine arm numbers.

Nominal three by 3.00m rows will also be handled by the previous generation KW7.70 /6×7 but such a tedder is likely to have lead a hard life, well-used examples selling from around £3,500 privately and at auction. Such a machine worked by an ‘enthusiastically’ driven 150hp tractor will be asking a lot of a tedder of this vintage. Do the same with a late KW 7.82 6×7 in good order, and you are more likely to be onto a winner. Late KW7.82 tedders retail from between £7,500 to £8,500. Expect a tedder at this sort of money to be in good order.

If you compare the build and driveline between first and second generation KW tedders it is clear Krone made significant changes to the design. In brief these include:

- Stronger ‘A’ frame headstock

- OctoLink eight-finger drive in place of UJs • Stronger main frame with larger pivots with greaseable pins

- Revised liquid grease immersed rotor bearings

- Stronger rotor tine arms

- Strengthened rotor guards

Changes Krone has made to the new Vendro series are listed separately, these later units also offering a slight increase in working width per pro-rata model.

WHAT TO LOOK FOR

Used equipment scarcity can mean it is tempting to buy something before looking it over. If you are not buying from a trusted source, be aware that there will be some good looking but well-worn tedders on offer. Key checks are simple enough but a proper inspection can take a couple of hours and, ideally, should include inspecting the tedder both when parked up and attached to a tractor and opened up ready for work.

Working back, start with the pto shaft, looking for damage and poor guards. A bent pto is not common but still check it runs true. Wear in the UJs will be a concern on older or heavily worked first generation KW models. The headstock on all variants is not a problem area but look for repairs and fractures. Check the pivot points are not worn.

If the main gearbox has been treated to fresh oil once a season it should be in good order, but still check for weeps from the shaft seals. It can be difficult to check for backlash, but it is worth having a look, a second person working a near rotor back and forth helping you pick up play. If you spot obvious wear, seek advice.

Most KW tedders will have stabilisers with renewable plastic damper collars. These wear items are easily overlooked and, when worn, will allow the tedders to pivot too freely in work. Cheap and easy to renew, it is worth investing in a spare set. The bump stops tend not to wear out but can age harden so it may be worth renewing them at the same time. Rust on the sliding sections of stored tedders is worth cleaning off as it will cause wear on the plastic damper collars.

The main chassis and related pivots are tougher on post 2007 KW models but even earlier examples tend not to have problems unless the tedder has hit something in work and been damaged. You can only check for this with the unit unfolded. This will also allow the rotor to be checked. In early models with UJ drive, check for backlash between the rotors, any obvious play needing to be investigated. The rotor bearings of this generation of KW are different to the later 2008 generation and are not as easy to renew if worn. If a rotor has play in the bearings, seek advice as the cost of a repair can be more costly than you would think. If a ‘cheap’ tedder has clear bearing wear in a couple of rotors, the chances are it is not worth considering.

The rotor guard system has various links and pivots, these non-load bearing items not being a problem if the guards are not bent. If there is some damage, do not dismiss as this may interfere with how the tedder folds. If KW tedders have a weak point, it is the guards as they do get damaged but are often not repaired or renewed. They do need to be in good order. If the guards are missing, don’t buy the tedder. Simple.

The tedder tines are obviously wear items, with the best way of determining if they are worn and need renewing being to compare old with new. It follows that the handed tines are best renewed as a complete set, so cost this in when considering a used buy. Also consider the cost of tine breakages, renewing old tines proving a good idea when preparing a crop for a forage harvester. A complete set of tines, with new fasteners, will set you back around £1,750 in parts on a KW 7.82 6×7.

The rotors each run on wheels, the tyres of outer units typically lasting well but still look for age-hardened rubber and sidewall fractures. The inner two tyres carry the weight of the tedder when it is folded, so ensure the sidewalls are in good order and that the tyres have not got a flat bottom that is common on units coming out of storage. Vendro tedders have an extra central stand to take the weight of the tyres to get around the latter.

With regards to other checks, check all adjustments, ensuring the various settings can be moved and have not seized. Although this sort of kit is best stored under cover, a unit surplus to requirements may have been left outside and forgotten for a while, so check.

SUMMARY

KW mounted tedders are simple bits of kit, sound early models making a tempting buy if well-priced. Pro-rata, however, the best models to go for are the later 2008 and onwards models, these benefitting from a more robust overall build that is more likely to suit heavy work behind a more powerful tractor.

Although new kit prices have spiralled over the past couple of years, cost in a new Vedro when considering a used KW buy. The latest Vendro models have a few design upgrades, and you can of course invest in a machine that will match your specific needs. Be realistic on delivery though. Current lead times could mean you have a long wait for one to arrive.

With thanks to James Alexander, Primewest, Enstone, Bruce Miller and Will Headington, Krone Forage Solutions, Oxfordshire and Krone UK.

For more like this subscribe to Agricultural Trader and Farm Machinery.