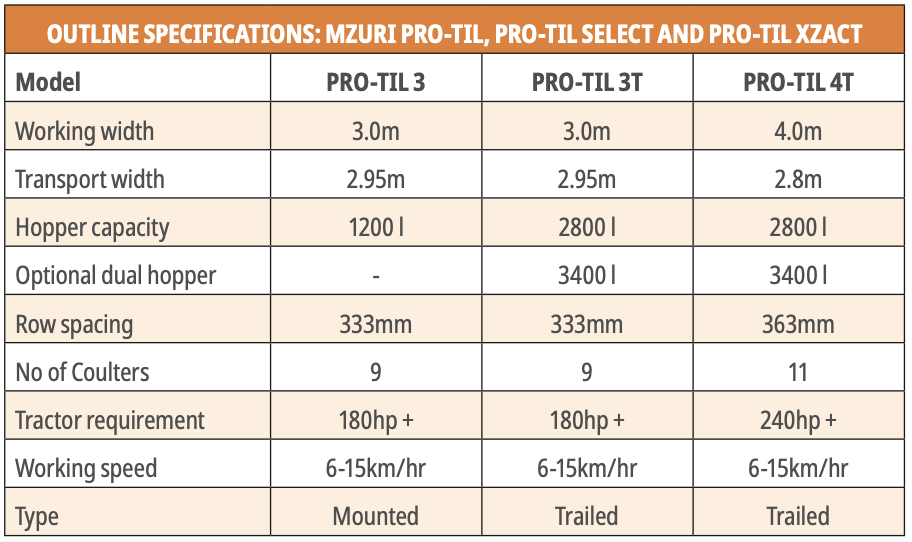

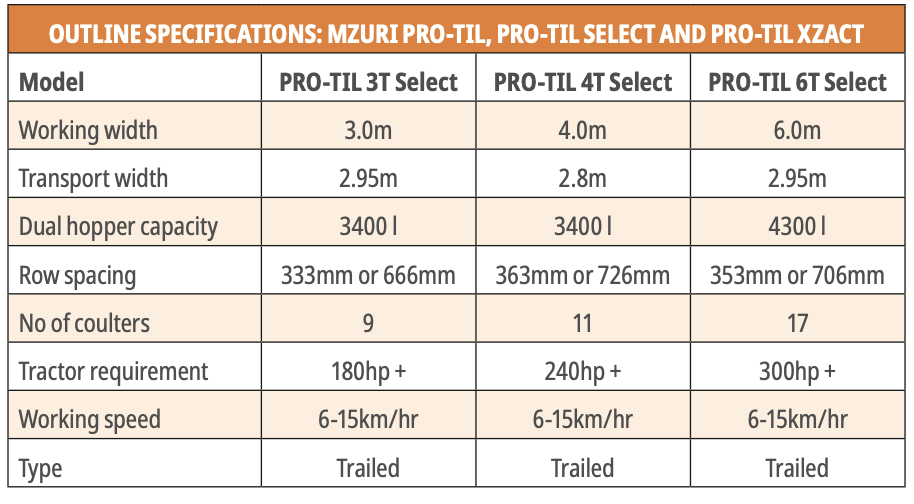

Mzuri launched its first Pro-Til drill in 2011, first as a 3.0m mounted model that was subsequently joined by a 4.0m trailed variant arriving in 2012. A decade on, and the Pro-Til range now includes trailed units of up to 6.0m, variable row spacing Select models and the option to add Xzact seed singulation metering. Despite an expanded offering, all variants of these drills stick to the original design concept, the earliest examples doing pretty much the same job as current models.

The Mzuri Pro-Til drills strip tillage sowing system has not changed from its original concept. In broad outline, staggered auto reset leading tines, fitted with boots to enable fertiliser to be placed in the soil at the same time, open up the soil and clear it of surface trash. Cleated tyres follow to carry the weight of the drill, the seed coulters that follow then sowing into the previously loosened, and the optionally fertilised, soil. Semi-pneumatic wheels control the depth of each individual seed coulter and firm the soil over the seed. A set of hydraulically controlled tine harrows then level off the seedbed, although not all drills have these.

The Pro-Til system has had the odd tweak and development, as you would expect, but a decade old Pro-Til will still do pretty much the same job as a current model. Of equal importance, some developments, such as a switch to the current front leg and wearing metal, can be fitted to older drills too, as can some of the newer options, such as front discs.

That said, two key elements cannot be modified. First, the original seed or seed/fertiliser hopper was designed to work with 500kg bulk bags with capacities of 1,000 litres for the mounted and 2,800 litres for the trailed models. This was just at a time when 600kg bags started to come on stream, leading to a mis-matched hopper to bag capacity. The original one-piece watertight hopper lid also opened to one side, pretty much restricting filling the drill with ‘big bags’ from the offside.

A key second change made to trailed models was a revised axle frame strengthened to accommodate the higher capacity hoppers. The revised frame also saw the inter-row spacing of the cleated tyres increased from around 230mm to 280mm, enabling Mzuri to fit larger wheels and tyres. Larger tyres help to improve soil consolidation behind the leading tines, the increase of ply rating from 8 to 12 allowing for higher transport speeds. Larger stub axles were also fitted, with brakes offered as an option. The central wheels, which carry the drill in transport, can be fitted with 18-ply tyres.

In 2015, Mzuri moved to Isobus control. This allows the drill to be plugged directly into a compatible tractors display, although a dedicated RDS sourced in-cab control box remained available. From a used buyer’s perspective, the key advantage of the Isobus system is its ability to operate slug pellet, micro granule or other applicators without the need for separate control boxes.

It is possible to update older drills to Isobus using an RDS Artemis Bridge Module, but the original control box will be fine for most users, the in-cab display recording all the drill’s operating data plus listing error codes should there be a fault, such as a low fan speed or failed sensor. These key changes out of the way, it is important to point out that there have been numerous other detail developments made along the line. Certain components have been changed or upgraded and most of these will be supplied as a direct retrofit should the original need replacing. Mzuri also carried out in-field modifications to some of the earliest drills to include replacing the original ‘plastic’ pneumatic fan to a redesigned alloy unit. The fan motor itself has also been revised, the 8cc item fitted to drills made up until around 2015 giving way to a more oil efficient 6cc unit. The latter is a relatively easy retrofit and will be supplied if the original needs to be replaced.

Look over an original and current drill and you may note a host of other changes:

- The fertiliser distribution head moved from outside to inside the hopper, with revised hose runs

- All sensors now have a short wire run and connector to the main loom to speed replacing any that may fail

- The seed and fertiliser hose diameters have been increased from 60mm to 80mm to help prevent constriction when tramline kits are fitted

- ‘Trademark’ Mzuri star head pivot pins are now one piece with no welding on the head

- GPS speed monitoring replaces radar

- The semi-pneumatic rear wheels are now round profiled smooth units in place of the still available flat design. Scrapers are an option

- LED work and transport lights

- Improved in-hopper lighting and cameras

Those familiar with these drills will spot other little changes, such as an alloy platform access ladder to replace the steel item used up until this year and further option choices to include a twin-row following harrow, ancillary applicator spreader plates and more. Existing models may be able to have recently developed options fitted, so check.

KEY USED CHECKS

Job one is to take in the overall condition. A drill that has been stored under cover, is clean and has been treated to some storage TLC will obviously make more detailed inspection easier. The Mzuri Orange paint hangs on well, the dark grey powder coated chassis standing up well to corrosion but still look for damaged and chipped paint. Not a problem area but stone chips can spoil the look of the drill.

Cosmetics out of the way, next look at the tines and coulters. On pre-2014 models, the coulter wings can be renewed separately and there was also a choice of narrow 75mm ‘bean’ and ‘standard’ 125mm widths. The main body of the coulter is secured by a couple of roll pins, making replacement quick and easy. On most ‘early’ drills, expect to find single hose ‘boots’ for both front tines and rear seed coulters, most drills sold having both fertiliser and seed metering. Seed only drilling on combine models is possible by simply removing a baffle between the fertiliser and seed sections in the hopper.

The design of the front tine legs and coulter and the rear seed coulters was changed in 2015 to a single piece unit with a revised tip to heel design to reduce wear and also cut draft. Both original and current coulters are made from Hardox steel as standard with tungsten wear plates as an option. The latter are considerably more expensive but they typically increase service life by up to three times.

The original designs are still available as a spare but around 80% of older drills have been modified with new legs to accept the current design. Mzuri occasionally run a spares campaign to encourage the move

to the current legs, the latter coming with a choice of four coulter widths, to include a new 25mm variant alongside widths of 75mm, 125mm and 250mm. The tine and coulter boots, incidentally, can have a single or twin hose attachment, the latter allowing cover or break crops to be sown alongside the main crop. All sowing is done within a band of around 125mm.

When looking over the wearing metal, check all leg and linkage pivot points. There are a lot of these on a Pro-Til drill! The pivots fall into two groups; those that need grease gun attention, such as the lateral pins that enable the seed coulters to pivot laterally, and the star pin types that run in replaceable Glacier bushes. The latter must be renewed when pivot play is detected to protect the parent bore from wear.

Pivot wear is a great indicator of past care, a point to consider if you are looking over a private sale or, for the brave, an auction buy. If the pivots are worn it suggests less than diligent care. Drills sold through Mzuri and its dealers will be prepared and ready for work, but still check the pivots. As we have already mentioned, there are a lot to check.

Moving to the metering system, the in-house designed and built system is driven electrically via an RDS Artemis controlled motor. Made from stainless steel, with the key bearings of the system open ball and nylon to help ensure they can be periodically cleaned and economically replaced. The fertiliser and seed units are of the same design with a choice of metering wheels to suit a broad range of materials and seeds. Typically, the metering units are not known for any problems, with just the easily renewed rubber control flap liable to wear or rodent damage. It is best changed every season.

The fertiliser hoses on the first drills run from the metering units to an external distribution head. Later models have the distribution head inside the hopper, with hoses running from the front of the drill. This shortens the hose run. All models use waste heat from the hydraulic coolers to dry and warm the air drawn into the pneumatics distribution system. This can really help improve seed and fertiliser flow in damp weather.

It pays to take a good look at all the hoses and check for damage. On the latest drill models, a modified hose retention system is fitted to prevent the hoses fouling when the drill wings are folded. This can

be retrofitted to existing drills and helps prevent hose rub and chafing.

Corrosion of dual fertiliser and seed hoppers is not normally a problem with the caveat that a lot will depend upon how the drill has been looked after. The watertight hopper lids do a good job in keeping water out if the drill is rained on in work but a thorough end of season hopper and system clean is still needed. When looking the drill over, check the hopper lids have not been damaged. This can easily happen during loading with big bags.

If possible, hook up a drill that has not been prepared for sale to a tractor, making a note that the hydraulic free flow return must be attached before any of the other hoses and removed last when detaching the drill. With the hydraulics under pressure, it should be easy enough to spot any seal leaks, damage to the hose runs and problems with hydraulic drive to the fans. The depth control systems use familiar fold in and out slices, with fine tuning of telescopic screw adjusters to set the semi- pneumatic depth wheels. Worth giving them a twist or two to check they are free and not damaged.

It is not that easy to check the front and rear wheel bearings but assume any drill with several thousand hectares of work behind it will probably need the odd bearing renewing at some point, particularly those of the inner ‘transport’ wheels. A pre-season service will identify any that have any play, so budget for replacements on any used drill that has yet to have any workshop attention.

An area that is often overlooked is the drawbar tongue. Bolted to the main chassis, the tongue can be renewed with a design to fit your requirements, those with a renewable swivel ball typically suiting most needs. If the tongue has an enlarged draw pin hole it should be renewed, play here spoiling how the drill follows in transport and leading to a ‘rocking’ motion in work.

This is a broad-brush check list; if you can hook up the controller it will provide a bit of drill use data and enable a check of the metering system to be made. But another important check is to see if the drill is still known to Mzuri. If you come across a private, auction or non-Mzuri dealer buy, pick up the telephone and contact the company.

Armed with the drill’s serial number, you can potentially learn a bit about the unit’s past, it’s possible value and get some good used buying tips into the bargain.

The best source of used drills is through the company direct. Used and ex-demonstration buys typically find a home through word of mouth, so again do not be afraid to ask if a used buy is likely to be available and if it has the right specification for your needs. Plain seed only drills are a rare used find, with mounted 3.0m having strong regional demand that can make them difficult to track down; the most popular used model is a 4.0m 4T trailed, with the adjustable coulter width Select version currently selling well due to its push button versatility.

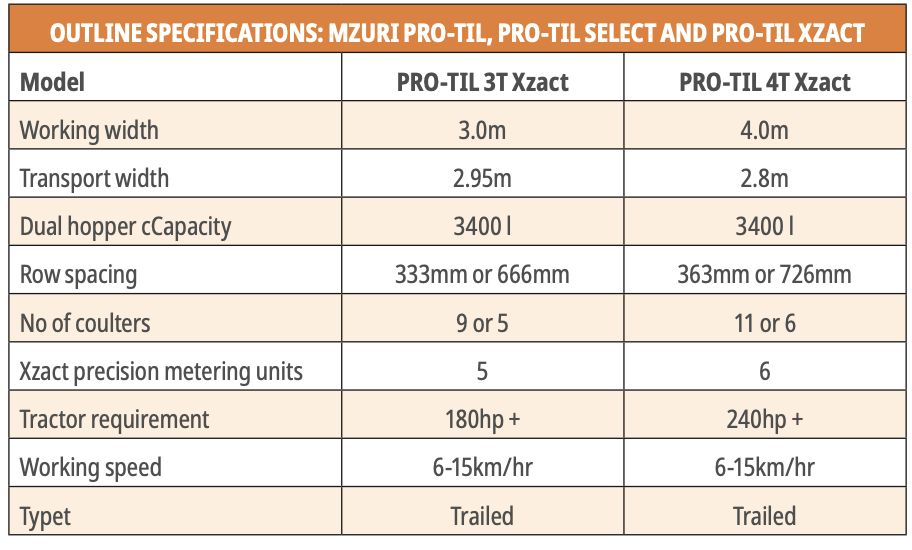

As an aside, the Xzact seed system has gained a great deal of traction in the UK, a key attraction besides the ability to strip till drill maize being the added ability to feed fertiliser to the seed slot and to use the hopper to bulk feed the metering units for much reduced downtime. The Xzact system can be fitted to existing Pro-Til drills but seek advice before making any assumptions.

SUMMARY

Does a pre-owned Mzuri strip till drill make a sound used buy? Yes, but these are high specification, well-made bits of kit, with Mzuri offering strong part exchange values to existing customers which in turn helps copper bottom residuals. A well-cared for and fully prepared older drill will command strong money, tired examples making a good project buy if you secure one for the right money but seek advice first.

As to models, it is the trailed Pro-Til 4T Select, with its easy to select row spacing, that is the current top seller, mounted seed only 3.0m models having a strong following in areas with narrow lanes between fields. The bulk of trailed drills will have a dual hopper for seed and fertiliser. As always, the best used buying advice is to do your own research, talk to existing users and ask questions.

I WISH SOMEONE HAD TOLD ME…

…to look at the seed in the row and not to drill too deep. A common problem is to set the front tines and seed coulters deeper than is necessary. It is pretty obvious that drilling too deep increases wear on the drill, makes the unit harder to pull and with it leading to increased fuel use.

… not taking the time to correctly ballast the tractor, adjust tyre pressures and check for level running of the drill. In level going, a tractor of 180hp will pull a Pro-Til 4.0T without too much trouble at working speeds of up to 15km/hr. Heavy going and steep land will up the power demand but a correct set-up should drill with low wheel slip, poor traction often being confused with high draft.

… to not be afraid of seeking help and advice. It can be the simple things that can turn a poor drilling experience into something a lot more positive.